"Hakurouu (白老)" Sawada Shuzo (澤田酒造) is a unique sake brewery on the Chita Peninsula that combines old and new - SAKETOMO's Sake Brewery Tour in Aichi Prefecture

In the fourth installment of SAKETOMO-style Sake Brewery Tours in Aichi, which introduces unique sake breweries in Aichi, we visited Sawada Shuzo (澤田酒造) in Tokoname City, Aichi Prefecture, known for its brands such as "Hakurou (白老)”.

The full body, uma-kuchi (sweet), robust sake brewed by this long-established sake brewery with a 175-year history has been favored by many sake lovers, especially locals. Sawada Shuzo was heavily involved in the development of the technology that became the foundation of the "fast brewing method" essential to today's sake brewing during the Meiji Era (1868-1912). Currently, the sixth generation of the brewery, Ms. Kaoru Sawada, has inherited the DNA of generations of sake brewers, who have continued to "evolve" while passing down the old ways, and is working on sake brewing together with young brewers.

In this interview, we asked Ms. Kaoru Sawada about her thoughts and beliefs about sake brewing unique to the Chita Peninsula, which have been handed down by the Sawada Shuzo, and about new attempts for the future.

-

Ms. Kaoru Sawada, the sixth president of Sawada Shuzo, and her husband, Mr. Hidetoshi, who has passed on the brewing of "Hakurou" in Sawada Shuzo.

Hakurou Sawada Shuzo (Tokoname City, Aichi Prefecture) https://Hakurou.com/

“Hakurou" by Sawada Shuzo was greatly involved in the development of the basic technology of sake brewing in the modern age.

Sawada Shuzo began brewing sake in 1848 in Tokoname on the Chita Peninsula, which was once the production center of Tokoname Ware and a prosperous shipping hub during the Edo period. The name "Hakurou," which combines the Chinese character for "white," meaning "to handle rice carefully and polish it until it becomes white and beautiful," and the Chinese character for "old," expressing the desire for longevity and the "skill of an old hand," to ensure that those who drink Sawada Shuzo's sake live long lives, reflects the sincere desire for sake brewing inherited from Giheiji Sawada, the first brewery's founder.

Mr. Sawada:

The Chita Peninsula, where Tokoname is located, has a relatively mild climate, but in winter, when sake is brewed, a cold wind called "Ibuki Oroshi" blows down across Ise Bay. In order to take in this cold Ibuki downpour and cool the brewery efficiently, Sawada Shuzo is arranged in an inverted L-shape with the northwest corner of the building. This inverted L-shaped structure is one of the common features of sake breweries on the Chita Peninsula.

-

Present-day Sawada Shuzo (South in the foreground, north in the background)

Sake brewing is still conducted in the buildings on the west and north sides.

The Chita Peninsula prospered as a base for the Bishu Shipping Company, and in the Edo period (1603-1867), sake could be delivered to Edo quickly by taking advantage of the mobility of shipping, and was also heavily patronized by the Owari Clan, the first of the three Tokugawa families. It was also easy to secure the high-quality water and rice necessary for sake brewing, as well as the labor force. For these reasons, sake brewing expanded rapidly on the Chita Peninsula. From the late Edo period to the early Meiji period, sake brewing grew to such a scale that it was known as the second largest sake brewery after Nada, and records show that at its peak in 1871, there were as many as 227 sake breweries on the Chita Peninsula.

However, with the impact of the Meiji Restoration and the shift in transportation from sailing ships to steamships and then to railroads, sake brewing on the Chita Peninsula began to decline.

In order to cope with such severe changes in the environment, sake breweries in the Chita Peninsula joined hands and organized the "Houjougumi” association. They worked to improve brewing techniques to ensure the survival of Chita sake. In the process, Giheiji, the third generation Sawada brewer, set up a brewing laboratory designated by the Houjougumi within the brewery. He also invited an engineer, Mr. Kamajiro Eda, from the Ministry of Finance to establish a brewing school and work on technological development.

Ms. Sawada:

The greatest fear in sake brewing at that time was "fuzo” (spoilage of fermentation mash)," or the rotting of the brewed ingredients instead of turning them into sake. Once the "fuzo" occurred, it could have a fatal impact on the business.

Therefore, Mr. Giheiji Sawada, the third generation of brewers, worked with Mr. Kamajiro Eda on research to prevent "fuzo” and developed a technique to make sake by adding lactic acid to shubo (fermentation starter). This technique became the basis for the "fast brewing method" that has become the standard for modern sake brewing.

I find it amazing that the "fast brewing yeast" technique, which was developed through the combined efforts of Chita sake brewers including Sawada Shuzo during the Meiji era, has become the foundation for today's high quality sake brewing. I hope that the spotlight will shine on it once again.

-

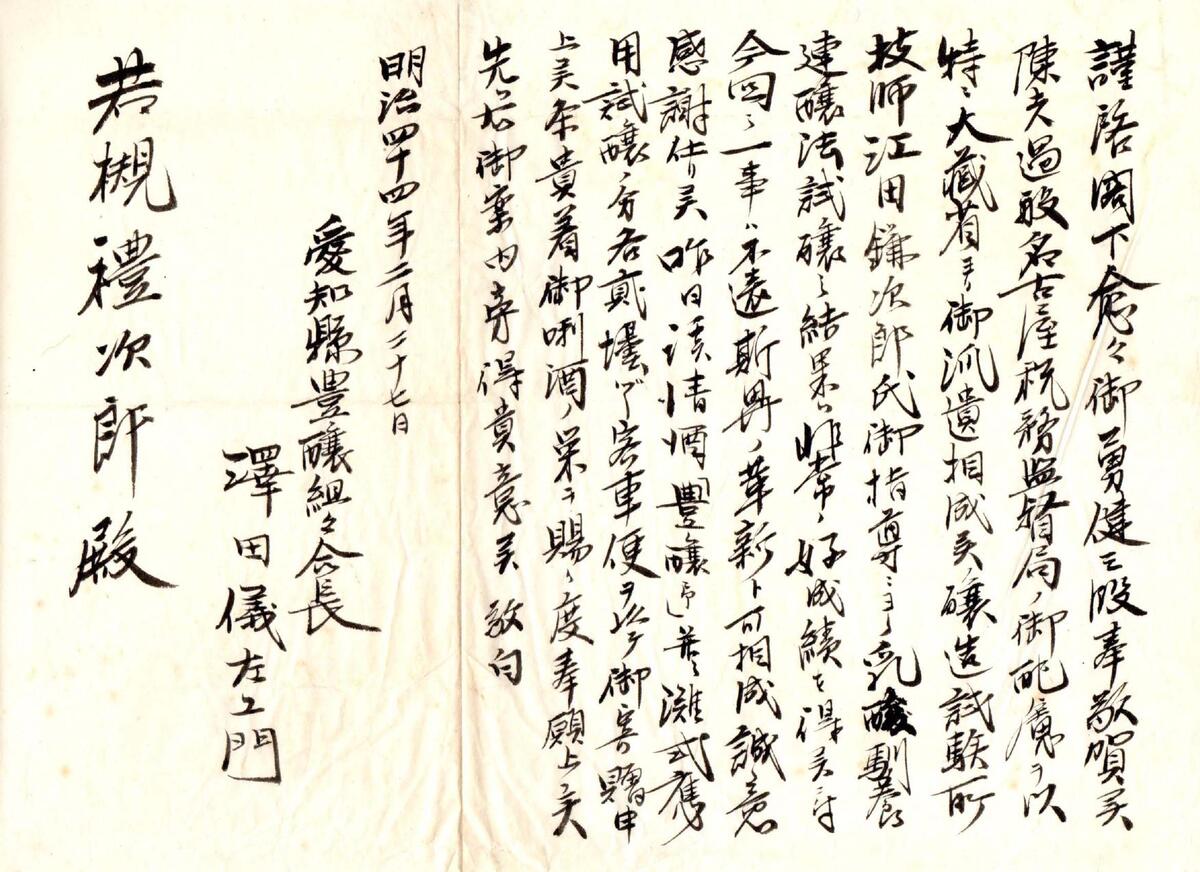

Letter sent from Gizaemon Sawada, who was the chairman of the Houjougumi, to Reijiro Wakatsuki, the Minister of Finance at the time

Ms. Kaoru Sawada, the sixth generation to inherit the Sawada Shuzo, which was a part of a major technological innovation in the history of sake, is the present-day inheritor of the brewery. Ms. Sawada was born the only daughter, but her parents never told her to take over the brewery.

Ms. Sawada:

I went to an English-related university because I liked English. When I was a university student, I attended the "Women in Breweries Summit (蔵女性サミット)," which was started by Rumiko Moriki, known for "Rumiko's Sake (るみ子の酒)," and I saw the female sake brewers who gathered at the event shining very brightly. In addition, I have always loved "food" and wanted to pursue food culture, so I realized that preserving sake culture was connected to that.

The difficult times for sake have continued for a long time, and the number of sake breweries in Chita has been decreasing rapidly. At Sawada Shuzo, there was even talk of closing the business at the time of the change from the previous generation to the next. However, fellow sake brewers encouraged Ms. Sawada, saying, "The things that have been preserved from the past, such as the wooden steamer and koji lid, are what differentiate us from other breweries," and she changed course. Under the slogan of "old-fashioned traditions," the brewery continues to make sake using traditional methods, but is also actively involved in new endeavors, such as opening the brewery to the public.

Ms. Sawada:

It is a wonder that we are still in business as a sake brewery, but we are still making sake with the single-minded desire to make good-tasting sake. In order to survive in such a severe industry, we must keep up with the rapidly changing environment. My father, who believed that flexible thinking by young people was necessary for this, said, "It is better for you to take over the presidency while you are still healthy" and handed over the presidency to me at an early date.

Ms. Sawada took over from her father in 2007, just two months after the birth of her second child. When she had just taken over as president, she sometimes held business meetings while breastfeeding her baby. Today, she is making sake together with young brewers, inheriting her father's passion and traditional methods.

-

President Kaoru Sawada answering an interview

“Old-fashioned tradition" is the slogan for the Hakurou sake brewing.

What kind of sake is Hakurou, the representative brand of Sawada Shuzo?

“Hakurou" is a mellow and delicious sake with the flavor of rice that is as strong and rich as the miso and tamari produced in this region. The company currently produces a wide range of sake, from regular sake to Daiginjo, but while regular sake is a sweet sake that is easy to drink after the sweat of the pottery craftsmen who fired up their kettles, the Honjozo (main brewery), as its name "karakara (dry dry in Japanese)" suggests, is a dry sake.

The brewery also produces Ginjo and Daiginjo, as well as "sake that only the brewer can drink," the first commercialized nama-zake (unpasteurized sake) in Japan, and Junmai-ginjo’s age-shu.

Rice and water are essential for sake brewing. Please tell us about your commitment to rice.

Ms. Sawada:

Currently, half of the rice we handle comes from Aichi Prefecture. Among them, "Wakamizu" and "Yumeginga" rice for sake brewing are mainly produced by contract farmers in the Chita Peninsula centering on Tokoname City. “Wakamizu" has been produced since around 2003, and its soft and soluble characteristics, combined with the flavorful characteristics of Chita sake, make it a sake that is uniquely Hakurou. We also use "Wakamizu" for Junmai-shu.

The other half of the rice is non-Aichi rice, such as "Yamadanishiki" from Tojo, Hyogo Prefecture, "Hattannishiki" and "Sembonnishiki" from Hiroshima Prefecture, and "Gohyakumangoku" from Toyama and Fukui prefectures. Gohyakumangoku, in particular, is used as koji rice for regular sake and "Karakara" by honjozo. Tojo's Yamadanishiki and Hiroshima's Hattannishiki and Sembonnishiki also produce very good sake, so we continue to use them while taking advantage of the characteristics of the rice from each region. The use of Hattannishiki and Sembonnishiki, which are not commonly used in this area, may be said to be part of the lineage of tradition inherited from our predecessors, who were quick to jump at anything unusual or different.

How do you secure the water for brewing?

Ms. Sawada:

There is a spring in the mountains about 2 km from the brewery, from which we obtain water for brewing through a private water supply.

The area where the Sawada Shuzo is located has a complex geological formation, and the quality of the water varies depending on the location of the spring. The main water we use is soft water with a mild flavor, but we also have a well that produces medium-hard water, which we use according to the timing of brewing. The medium-hard water from the well is used for making shubo (fermentation starter), as it allows the yeast to work more vigorously.

Fortunately, this water has never run dry, and we are truly grateful that we have been able to secure clean water since the company was founded. The sky, oceans, and mountains are all connected by water, and I would be happy if a part of the water in this cycle is turned into sake, which people can enjoy and feel that humans are part of nature's workings. In the future, I would like to make sake with the same rice and yeast but with different water and compare the tastes.

-

The brewing water has been used since the Edo period. The water is supplied to the brewery by a private water supply from a water source about 2 km away.

The key phrase in Sawada Shuzo's sake brewing is "old-fashioned tradition”. What areas in particular are unique?

Ms. Sawada:

I think the most characteristic parts of Sawada Shuzo are the "wooden koshiki (steamer)" and the "koji-buta (shallow wooden trays for koji) ”.

“Koshiki" is a large vessel used to steam rice, and wooden steamer is still used at Sawada Shuzo. Wooden steamer has many advantages: it has excellent heat insulation and heat retention properties, so it can steam rice well; the temperature rises slowly, so the entire rice can be steamed evenly; and the humidity control effect of the wood prevents excess moisture from transferring to the rice, so the so-called "koshikihada (steamer skin)*" is less likely to form. In a word, the reason why we still use wooden steamer is "because it can produce good steaming.

However, there is a disadvantage of using a wooden steamer that it requires a lot of fuel and is inefficient. It is especially difficult when the cost of fuel goes up, because it is a factor that increases costs.

The wooden steamer we are currently using was made by a craftsman in Handa-city and repaired by a craftsman in Sakai (Osaka prefecture) a few years ago. The number of barrel craftsmen is decreasing, but in Nada(Hyogo prefecture) and other areas, a woodworking factory has been established to train craftsmen of wooden barrels, so I hope to ask them to repair our barrels in the future.

*Koshikihada: Steamed rice in contact with the steamer absorbs water on the surface and becomes soft.

-

The wooden steamer currently in use. The steamer is placed on top of the banner pot at the back left of the photo to steam rice.

Ms. Sawada:

Another "koji-buta" is a small container used for koji making, and koji making using this koji-buta was already being done around the middle of the Edo period. It is the smallest container used for koji making, and allows koji to be made uniformly by dividing rice sprinkled with koji mold into small portions and placing them on a shelf to cool.

Sawada Shuzo also uses 200 to 300 koji covers, which require a lot of manual labor. Sawada Shuzo is the only brewery in Aichi Prefecture, and one of only a few in Japan, that consistently uses koji-buta for everything from regular sake to Daiginjo. Even so, we believe that the use of koji-buta produces a firm koji called "sohaze type", which enables us to produce the mellow and flavorful sake that Sawada Shuzo is aiming for. Craftsmen also find it rewarding to put their heart and soul into their work.

Sawada Shuzo experienced a major incident in November 2020, when the koji room, which is the key to sake brewing, was destroyed by fire. Could you tell us about that time?

Ms. Sawada:

The fire in the koji room was caused by a short circuit in the electric wire called heater wire that was stretched to heat the koji room. Heater wires are a common cause of fires, so we checked for leaks that year, but unfortunately it led to a fire.

Fortunately, we noticed the fire at noon. A brewery employee discovered the fire around 1:00 p.m. and came to report it to us in a panic, but a childhood friend of mine who happened to be a firefighter at the time came to buy alcohol for the first time in about 20 years, and we were able to put out the fire immediately.

However, the koji room was burned down, so to be honest, my mind was blank at first, and I thought, "This is it.” ...... However, since the koji room was in a fireproof building, other parts of the brewery, raw materials, seed koji, etc. were safe.

The day after the fire, Mr. Yamada, the president of "Gikyo (義侠)" rushed to me and said, "We can make sake as long as we can manage the koji." He told us to come and make sake at our place, and with the help of the Yamachu Honke Shuzou (山忠本家酒造), we were able to start koji production. We were also able to ask Sekiya Brewery (関谷醸造) for help because we were classmates when we were both toji at vocational school, and Maruichi Syuzou (丸一酒造) for "Hoshiizumi (ほしいずみ)" and Moriki Shuzo (森喜酒造場) for "Rumiko's Sake", both in Chita. Thanks to everyone's support, we were able to resume sake brewing on January 20, the beginning of the new year. I am truly grateful.

Is the reconstructed koji room in the same shape as it was before the fire? Or is there any difference from before?

Ms. Sawada:

Since we had decided to build a new koji room, we decided to build the best one we could, so we consulted with Nitto Kogyosho(Tochigi prefecture), the only company in Japan that specializes in koji rooms, and proceeded with the reconstruction. In fact, the conventional koji room had only one room, and the floor for sprinkling koji, the part for keeping the koji moist and wrapping it, and the part for drying it by putting it on shelves lived together. It is tough to do moisturizing and drying in the same place.

In the new koji room, we divided the room into four compartments, each of which has its own temperature control system. We have also adopted safer plate heaters for temperature control. In addition, we have set up a shelf room for Ginjo to produce koji suitable for Ginjo, and a "dekoji room" with a refrigerated dehumidifier to produce higher quality koji.

The koji room was reconstructed with a wooden structure in order to make koji with a koji-buta, but modern technology was incorporated throughout to create a "moderately up-to-date" koji room.

I understand that you reconstructed the koji room with a wooden structure, but I think that a new wooden building may have a peculiar smell. How do you think about that?

Ms. Sawada:

It comes out a lot. Sometimes people say, "It's tarusake (cask sake)," and the wooden aroma is considered an off-flavor in the sake competition. We are taking various measures, but it will take a few more years for the aroma to settle down.

However, the general public enjoys drinking it, saying, "It has a slight woody aroma," so we hope that they enjoy it even if it does not pass the contest.

-

Koji room rebuilt after the fire

When the room was rebuilt, it was made "moderately up-to-date" by improving both safety and quality.

Not only preserving the old, but also taking on new challenges

Sawada Shuzo, which upholds the "old-fashioned traditions," continues to implement a variety of new initiatives. How did one of these initiatives, the cultivation of locally grown rice for sake with reduced agricultural chemicals, come about?

Ms. Sawada:

We started the sake rice cultivation initiative with contract farmers in Chita in 2003. In order to reduce mutual risks as we increased production, we increased the number of breweries to five and contracted farmers to several, and we have been able to have them produce high quality Chita sake rice with reduced use of agricultural chemicals. The sake brewery is only possible with the help of the farmers, and we are very grateful to have them produce good sake rice.

However, 20 years have passed since the start of the business, and the contract farmers are aging. While sake breweries have been replacing their workers in recent years, few farmers have been replaced by new ones, so I feel that there are challenges ahead.

You are also working on using "sake kasu (pressed sake cake) "as animal feed. Please tell us about it in detail.

Ms.Sawada:

About 4years ago, we started working with a farmer named Mr. Oiwa, who raises Chita beef in Minami-Chita, to promote the use of sake kasu as feed. Sake kasu have been widely consumed in this area because of the popularity of "karimorizuke pickles", but due to the aging of the population, there is gradually a surplus of sake kasu. We were wondering what to do with the sake kasu since it costs a lot of money to dispose of them, but we met Mr. Oiwa just in time and he made an effort to convert the sake kasu into fermented feed. Nowadays, the fermented feed using sake kasu is used not only for Chita beef but also for Nagoya Cochin and Chita pork.

Our activities have expanded to include a gift catalog that allows customers to enjoy pairing sake with beef, pork, and chicken raised on fermented feed using sake kasu. While circulating sake kasu in the community, livestock producers and butchers are adding new value to the product.

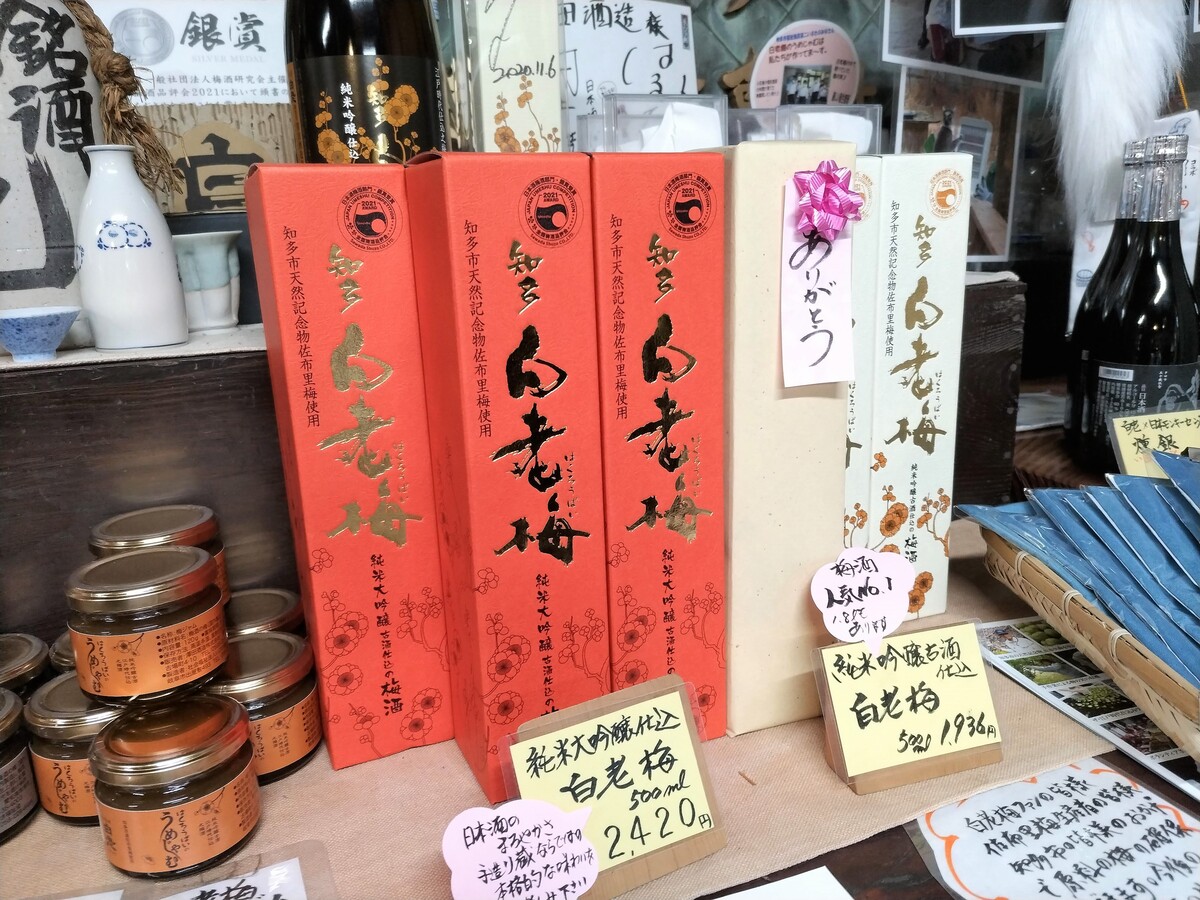

There is no reason why beef, pork, and chicken raised with sake kasu and sake should not go well together, right? As another initiative with the local community, Sawada Shuzo also focuses on the production of "Hakuroubai (白老梅)” using plums, a specialty of the region. How did "Hakuroubai " come into being?

Mr. Sawada:

"Hakuroubai" is a plum wine developed by my father. About 20 years ago, local farmers in the Souri district of Chita City, north of Tokoname, started a movement to revive the souri ume plums, which had been produced since the Meiji era (1868-1912). At around the same time, Sawada Shuzo was also gaining momentum to make a sake-based plum wine, and decided to use the locally grown souri ume plums.

“Hakuroubai" is made by faithfully reproducing the recipe for plum wine brewing as described in "Honchoshokkan (本朝食艦)," a book published in the Edo period. For example, straw from the "wakamizu" harvested from Sawada Shuzo's rice fields is burned to make straw ashes, and the plums are soaked in water containing the straw ashes to remove their scum. The plums are green souri ume plums, and the sake is old Junmai Ginjo sake brewed for " Hakuroubai " according to the "Honchoshokkan" recipe. Also, for the iced sugar, we use what is called "rock," which is made from sugar from Hokkaido and naturally crystallized for more than two weeks.

Sawada Shuzo has always made use of the natural blessings of the Chita Peninsula in its sake brewing, and I hope that " Hakuroubai " will once again be connected to such a trend.

-

“Hakuroubai" unique to Sawada Shuzo, made using local "souri ume plums" from Chita and reproducing the Edo period production method.

Please tell us about your efforts in the field of gastronomy, which started in 2023.

Ms. Sawada:

Sawada Shuzo holds an autumn brewery festival, where we have been holding events on the theme of fermentation and brewing in Aichi and the Chita Peninsula. This year, we have planned an event for enjoying Chita's gastronomy to let people know about the richness of Chita's bounty from a different angle.

I believe that the Chita Peninsula is a truly rich and blessed place in Japan, with its agricultural and livestock products, marine products, history, and brewing culture. Gastronomy is often associated with fine gastronomy, but one aspect of gastronomy is to value things that are connected to the land. We thought it would be fun to do something new with local producers and chefs.

We would like to continue to do various things so that people can enjoy spending time with sake. We would like to do things that we can all be proud of, so that we can continue our livelihood in a sustainable manner while working together with the people around us to preserve what we think is important.

As a brewer, how would you like people to enjoy "Hakurou" and "Hakuroubai"?

Ms. Sawada:

We make many variations of Hakurou, so you can enjoy them in different ways. Many of them go well with warmed sake, while others, such as the unpasteurized ones, are recommended to be drunk chilled. We also have strong-flavored dark sake, so I think it is good to drink it like a highball. We hope you will enjoy drinking it as much as you like.

"Hakuroubai" is based on Japanese sake, so we think you will enjoy it even if you drink it straight. "Hakuroubai" is also delicious on the rocks, and can be enjoyed in the hot season when it is lightly mixed with carbonated water at a ratio of 7 parts Hakuroubai to 3 parts carbonated water.

What kind of food or snacks does it go well with?

Ms. Sawada:

You can enjoy it as you like, but it goes well with the dark flavors that are popular in this area. It goes well with dishes that use basic soy sauce, and tamari is even better.

Dried fish is a good match. Dried whitebait tamari, a local delicacy, goes very well with tamari, and other than dried fish, sashimi of shellfish also goes well.

An unexpected pairing is the unfiltered, unpasteurized sake called "sake that only the brewer can drink (蔵人だけしか飲めぬ酒)," which goes well with raw oysters and blue cheese. "Houjou (豊醸)", a Junmai Ginjo sake aged for 5 years, also goes well with dishes with rich cream sauces.

It also has a salty taste, so it goes well with dried fish and other sea food. The rest of the flavor character varies greatly depending on the sake rice used. For example, light nigori sake from Gohyakumangoku has a slightly bitter and astringent taste, so it goes well with meat-based dishes, while Yumeginga sake, which is characterized by its clear flavor, is highly favored by Japanese food chefs.

“Hakuroubai" goes well with seafood, fried foods, and smoked foods. “Yukari” rice crackers from BANKAKU is the best match.

“Hakurou" by Sawada Shuzo, a fusion of "old-fashioned tradition" and "evolution," aiming for its 200th year in 25 years.

Sawada Shuzo has been carrying on the time-honored tradition of sake brewing under the slogan "Koshiki Densho," or "old-fashioned tradition”. However, when we look into the history of the brewery, we find that it has also made many pioneering efforts to meet the needs of the times, and has a tradition of firmly combining the "goodness of the old" with the "goodness of the new”. Perhaps one manifestation of this is the fact that Ms. Sawada succeeded to the position of president only two months after the birth of her second child.

Ms. Sawada Kaoru, the sixth generation, is also working together with the young brewers and many people around her to take on various challenges in preparation for the new era. The DNA that has been cultivated at Sawada Shuzo, a fusion of "old-fashioned tradition" and "evolution," has been firmly passed down to the Reiwa era.

-

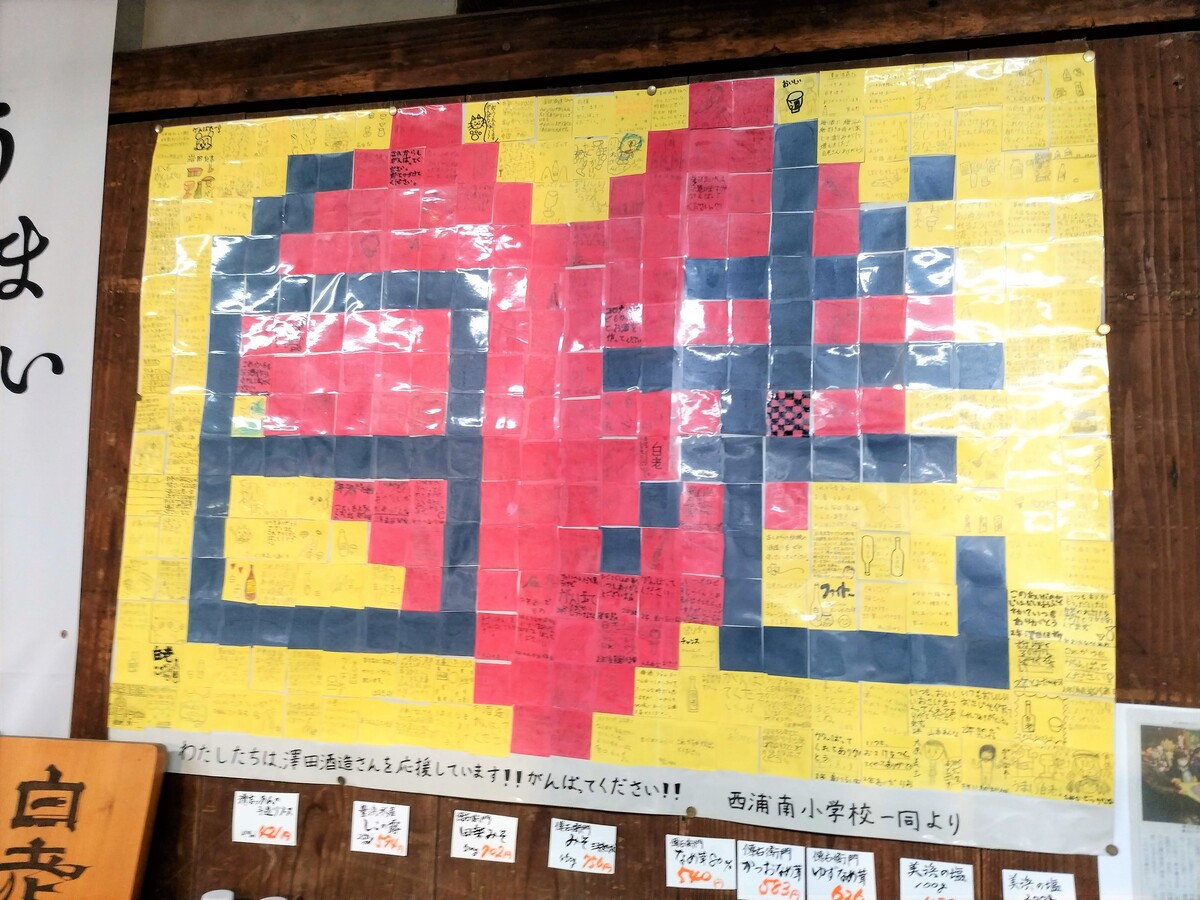

Sawada Shuzo, which has been working together with the local community, had posters of local elementary school students' handwritten messages at its store.

For those who want to know more about Hakurou by Sawada Shuzo, information on the store, brewery tours, and events

Shop hours: 10:00-16:00, closed on Sundays and national holidays, closed during the year-end and New Year vacations.

For more information, please visit the Sawada Shuzo website.

Sake brewery tours are available; please apply through the website.

Events: The brewery opens its doors to the public in late February, and an autumn brewery festival is held on the first Saturday and Sunday of September. This year the event “Enjoying Chita's Gastronomy" will be held on May 27 in 2023.

Please check the website and official social media (Facebook Instagram Twitter) for details of the event.

Affiliated Shop Cafe Gallery Tokonameya

3-111 Sakae-cho, Tokoname-shi, Aichi

TEL. 0569-35-0470

Open 10:00-16:00, also open on Fridays only from 18:00-22:00, closed on Mondays.

Ms. Sawada:

"Tokonameya" is a gallery and coffee shop that my father established with volunteers 28 years ago, serving coffee brewed with brewed water from Sawada Shuzo. A recommendation on the lunch menu is “Tokoname Chirashi”. It is hand-rolled sushi made with sashimi or pickled fish from the surrounding seas, served with Tokoname seaweed and stewed local beans that have been eaten locally.

Also in the immediate vicinity of Sawada Shuzo is a Swiss bakery and a car shop that sells many bamboo craft items. If you are willing to stretch your legs a bit, the INAX Live Museum and the "Tokoname Yakimono Sanpomichi (Pottery Footpath) "are also recommended. From the beach behind the warehouse, you can enjoy the view of Central Japan International Airport and the sunset.

Where you can buy Hakurou

Also available at online stores